Very short lead times

Industrial grade quality

From proto to serie

Engineering support

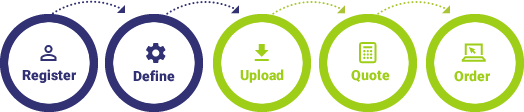

User-friendly platform

Strong partnerships

myProto keeps track of every single PCB prototype assembly project. For every project myProto has produced, we have documented the origins of every single component. Also, all the processes used to assemble your prototype printed circuit boards are recorded.

As a result of knowing the full extent of the assembly process, myProto guarantees traceability. From every single PCB component to ESD package used, and from our suppliers to your doorstep. Your prototype PCB assembly is traceable every step of the way!

“Made by engineers for engineers”. This is the best way to describe the myProto platform. Originally the prototype PCB assembly platform was developed as an in-house tool for our teams of engineers. It enabled our engineers to easily access suppliers’ stocks and get competitive prices throughout the whole PCB assembly prototyping process.

We realised that this tool could be made public to help other engineers. The PCB prototype assembly platform allows engineers to have access to industrial-grade manufacturing machines and produce high-tech projects in a fast and secure manner.

myProto’s customers come from various markets and industries.

Great service, quality and customer care.

Thank you for allowing me to perform a validation test on a sample in your premises before launching the whole batch to assembly. Also, the technical newsletter is quite informative.

Very happy with the short lines. The platform works well, but it is good to know that there is a person on the other side who is ready to help you.

myProto is fast, reliable and very proactive, securing the prototyping phase of a product

myProto has a good marketing strategy, which I think is unique in the segment of PCB services.

Read more

The speed and the follow up where amazingly good. I was really amazed about the speed and the accuracy to have my prototypes on my desk on the 6th working day!!

Thanks to myProto expertise, we can fabricate our mini-evaluation boards and respond quickly to our customers demand.

Read moremyProto was founded in 2017 by the engineers of DVC NV. DVC is a renowned engineering company in Europe that supports customers in developing and producing electronics since 1987. DVC develops hardware and embedded software, as well as a complete package of Electronics Manufacturing Services.

Member of