Design rules are not there to make designers miserable.

myProto is a member of the EDM Forum of imec (formerly cEDM). We spoke with Geert Willems of the EDM Forum about the role of a PCBA prototype, common mistakes and engineering tips for a perfect prototype. The aim of the EDM Forum is to provide scientific and technical knowledge about the design, production, testing, maintenance and recycling of electronics. The EDM Forum focuses on the non-functional aspects of electronics – also known as Design-for-eXcellence (DfX) – such as manufacturability, quality, cost, testability, reliability, etc.

myProto is a member of the EDM Forum of imec (formerly cEDM). We spoke with Geert Willems of the EDM Forum about the role of a PCBA prototype, common mistakes and engineering tips for a perfect prototype. The aim of the EDM Forum is to provide scientific and technical knowledge about the design, production, testing, maintenance and recycling of electronics. The EDM Forum focuses on the non-functional aspects of electronics – also known as Design-for-eXcellence (DfX) – such as manufacturability, quality, cost, testability, reliability, etc.

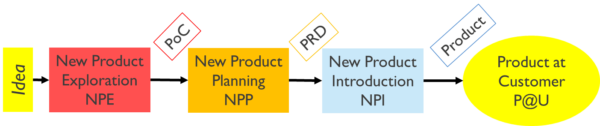

To be able to speak about the role of a prototype, according to Geert Willems, we first need to have a clear idea of what a prototype is. Geert Willems: “There are different types of ‘prototypes’ with different objectives.

For each type of prototype, there are specific test or evaluation goals. In order to achieve a fast, efficient and effective development process, it is important to avoid anything that makes achieving the prototype goal difficult. Production quality plays a very important role herein. Quality errors such as open solder joints or finding wrong components on a PCBA in development is difficult and time consuming. Investing in product testing such as “flying probe testing” and automatic optical inspection (AOI) is not an unnecessary luxury, especially if the assembly becomes more complex. As the development process progresses, the prototypes become more expensive. The lead time of a prototype iteration is also longer, not in the least due to the long delivery time of some components. This is especially true for the product prototypes. Here “right first time” is the goal. ”

Geert Willems: “Quality primarily depends on the design. The PCB manufacturer and assembly factory must of course have good process knowledge and control, but even the best factory cannot do a good job with a poorly designed PCBA. Garbage in is garbage out. Design-for-Manufacturing is certainly also important for prototypes. People often say “it is just a prototype, we will arrange those (layout) rules later”. But often in the end, it just does not happen and quality problems arise. Valuable time is lost to solve these problems. Our Design-for-Manufacturing guidelines on PCB, component and assembly specifications are, therefore, highly recommended when designing prototypes. This prevents a lot of mistakes.”

Geert Willems does not have hard figures about the most common mistakes, but there are errors that he regularly sees. Geert: “A good example are incorrectly placed components. The main cause is that different CAD systems use different reference systems for position and orientation of components. Furthermore, the following things often occur: the lack of “fiducials” required for automatic assembly, too little or no consideration of the assembly processes so that (too much) manual assembly work is required, component footprints with errors, insufficient solder flow in holes of through-hole components, etc. The physical design is typically the weakest link. ”

According to Geert Willems, the main problem is that DfM and other DfX aspects are not included from the beginning. “Companies usually focus on functional design: What does the electronics do? This is of course very important, but if the design cannot be produced with the necessary quality and at sufficiently low cost, it will never be a success. Design-for-Manufacturing, Design-for-Reliability and other DfX aspects should be treated at the same priority level as the functional aspects from the beginning of the development process. Adjusting afterwards is usually very difficult. Design-for-Manufacturing and testing is also important for prototypes. Design rules are not there to make the designer’s lifes difficult. They are there to quickly produce high-quality electronics without having to be a PCB or assembly technology specialist. Devoting some extra time and effort to this, e.g. by including DfX design review, will be catched up easily in the remainder of the development process. It usually saves time and reduces costs through less and faster evaluation and fewer iterations.”

myProto is affiliated with the EDM Forum to keep up to date with the latest developments and the latest insights. myProto uses the information to improve their online PCBA platform, but also when checking customers’ designs before producing them. myProto aims to treat and produce prototypes in the same way as series. As a result, we want to remove the production errors during the prototype phase!

The aim of the EDM Forum is to provide scientific and technical knowledge about the design, production, testing, maintenance and recycling of electronics. Geert Willems: “We focus on the non-functional aspects of electronics – also known as Design-for-eXcellence (DfX) – such as manufacturability, quality, cost, testability, reliability, etc. These are topics that electronics engineers do not learn while studying at college or university. In the past, this knowledge was acquired in the large vertically integrated companies such as Philips, Siemens or Alcatel that had their own production. Companies like this disappeared from the European industrial landscape around the turn of the century. The EDM Forum aims to bridge the resulting knowledge gap between design and production with DfX guidelines, resources, seminars, training and individual advice. All information is freely available to members via the website www.cedm.be.

The EDM Forum focuses on the entire electronic supply chain. It offers a helicopter view of the chain and aims to promote communication between the various links, so that chain-spanning product optimization can be achieved. It is not because the PCB or components can be purchased cheaper that the end product becomes cheaper. On the contrary, problems with quality and reliability can lead to a high extra cost. That is why people active at the interfaces between the links (design-PCB-assembly-purchase-quality-maintenance …) are an important, perhaps the most important target group. Our DfX guidelines help to specify, design, quantify and evaluate the various aspects of electronic assemblies (PCBA). They are designed in such a way that non-specialists can also work with them, although a certain basic knowledge is always required. We offer this in our technology seminars (PCB production, assembly technology, reliability).

We also have a more in-depth offering for the specialized designer, process engineer or quality manager. For more information: www.cedm.be.

Member of

🔧 Platform upgrade in progress – Stay connected!

We are currently upgrading the myProto platform to serve you even better. In the meantime, feel free to email us your project files (BOM, Gerber, Centroid, Lead Time & quantities) directly at 👉 quotation@myproto.eu.

We’ll be delighted to provide you with a quote as quickly as possible!

You can of course still use the current version of the platform if you prefer.