News

myProto is proud to announce a new partnership with Safe-PCB.

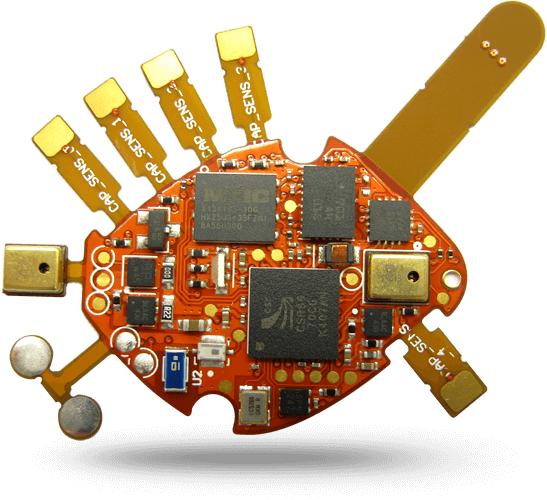

myProto is proud to announce a new partnership with Safe-PCB. This new supplier is part of the ever-growing desire to offer you the largest choice in different technologies for your PCBAs. The myProto platform can now calculate a price online for a prototype PCB assembly with six different PCB materials immediately.

You could already get an estimate for FR-4 and IS 400. Thanks to this new partnership with Safe-PCB you will now receive a price for the following PCB technologies:

Read more about the different PCB technologies.

FR-4 is a common material for printed circuit boards (PCBs). FR stands for flame retardant, and denotes that the material complies with the standard UL94V-0. FR-4 glass epoxy is a popular and versatile high-pressure thermoset plastic laminate grade with good strength to weight ratios. There is near zero water absorption. The material is known to retain its high mechanical values and electrical insulating qualities in both dry and humid conditions. These attributes, along with good fabrication characteristics, lend usefulness to this grade for a wide variety of electrical and mechanical applications.

For a PCB a thin layer of copper foil is laminated on one or both sides of an FR-4 glass epoxy panel. These are commonly referred to as copper clad laminates.

IS400 is intended for multilayer printed circuit boards (PCBs) applications where demanding thermal performance and high reliability are required. IS400 laminate and pre-impregnated (prepreg) products are manufactured using Isola’s patented technology, reinforced with electrical grade (E-glass) glass fabric.

The use of Insulated Metal Substrate (IMS) printed circuit boards (PCBs) is a good method for heat dissipation. This method is generally used for simple single-layer circuits. IMS is a special but very effective method of heat dissipation for components across circuit boards. These generally consist of aluminium supports, insulation layers and copper foil. The base materials are available in different design versions. The heat generated by components such as LEDs and transistors can be easily spread and transmitted. Compared with conventional FR4 materials, the heat conductance value of the insulating layers between the copper layer and metal carrier is 5 to 10 times higher.

Polyimide material is regularly used in flexible printed circuit boards (Flex PCBs). Polyimide PCB material is lightweight and flexible and great at resisting heat and chemicals. This material is widely used in a range of electronics, not just printed circuit boards. It serves as an adhesive that resists high temperatures as well mechanical stresses. The polyimides that are used in the Flex PCBs are generally imide monomer polyimides.

Composite Epoxy Material (CEM-3) 3 is a relatively new material for Printed Circuit Boards (PCBs). CEM-3 material is based on FR-4. CEM-3 is also made from woven glass fabric surfaces and non-woven glass core combined with epoxy synthetic resin. CEM-3 usually has a milky white colour. CEM-3 is very widely used in the production of double-sided PCBs with plated holes. The properties are very similar to that of FR-4, except for the lower mechanical endurance. CEM-3 is a less costly alternative to FR-4 for most applications. Laminates have a good ability to mechanical processing (milling, punching).

Rogers material is a dielectric material that is used for RF Printed Circuit Boards (PCBs). A dielectric material is a substance that is a poor conductor of electricity, and used as an insulating layer in the PCB build-up. The lower the dielectric loss, (the proportion of energy lost as heat) the more effective the dielectric material. If the voltage across a dielectric material becomes too great — that is, if the electrostatic field becomes too intense — the material will suddenly begin to conduct current. This phenomenon is called dielectric breakdown. Rogers is less likely to demonstrate a dielectric breakdown condition than FR-4. Rogers Material is used for advanced electronics designs like RF, Microwave and mobile designs.

myProto was founded by the engineers from DVC. This means myProto is perfectly capable to advise on the PCB material to be used for your PCBA prototype. If you need any advice, please contact myProto.

Create an account and start your project

Member of

🔧 Platform upgrade in progress – Stay connected!

We are currently upgrading the myProto platform to serve you even better. In the meantime, feel free to email us your project files (BOM, Gerber, Centroid, Lead Time & quantities) directly at 👉 quotation@myproto.eu.

We’ll be delighted to provide you with a quote as quickly as possible!

You can of course still use the current version of the platform if you prefer.